Scoping Study on Breakthrough New Processing Route

|

Emmerson PLC / Ticker: EML / Index: AIM / Sector: Mining

1 February 2024

Emmerson PLC ("Emmerson" or the "Company")

Scoping Study Completed on Breakthrough New Processing Route and Updated Financials

Emmerson PLC, the Moroccan focused potash development company, is delighted to announce the results of an in-depth scoping study on a new, innovative processing route (the "Scoping Study") at its 100% owned Khemisset Potash Project ("Khemisset" or the "Project"), which significantly reduces the Project's environmental impact and enhances its economic returns.

Highlights

Khemisset Multi-mineral Process

· The Scoping Study sets out a ground-breaking proprietary processing method named the Khemisset Multi-mineral Process ("KMP")

· KMP involves the treatment of brine to remove magnesium and iron chlorides through the addition of phosphate and ammonia, allowing the residual brine to be recycled in the plant

· KMP offers significant environmental benefits by eliminating the need for deep well injection ("DWI") and reducing water consumption by approximately 50%

· KMP creates two new slow-release fertiliser products, struvite and vivianite, while also increasing the recovery rate of Muriate of Potash ("MOP") from 85% to approximately 91%

· Struvite and vivianite command a price premium as multi-nutrient, slow-release fertiliser products, which reduce phosphate run-off and enable less frequent application by farmers

· KMP delivers a further substantial boost to the Project's economics, increasing the post-tax NPV8 by 120% to US$2.2 billion and delivering an exceptional post-tax IRR of 40%

· KMP has significant value as intellectual property with additional potential licencing revenues. The Company currently has a patent pending

Financial Updates

· Financial estimates for the Project updated from the feasibility study announced in June 2020 (the "2020 Feasibility Study"), both for the production process as originally designed ("Original Design"), and incorporating the KMP (the Project, including the KMP, being the "KMP Process Solution")

· KMP substantially improves the Project economics:

o Post-tax NPV8 of US$2.2 billion (Original Design without KMP updated to NPV8 US$1.0 billion)

o Post-tax IRR of 40% (Original Design IRR updated to 26%)

o Annual EBITDA US$440 million per annum (Original Design US$258 million)

· Total Project capex (incorporating KMP) now estimated to be US$525 million (Original Design capex US$539 million), reflecting industry-wide cost inflation since 2020

· All-in sustaining cost of US$163 per tonne ("/t") positions the Project at the lower end of the cost curve and delivers robust returns across a range of potash price assumptions

Environmental Approval

· The Company is still awaiting notification from the Commission Ministérielle de Pilotage (''Ministerial Committee'' or the ''Committee''), to whom the Khemisset environmental approval was referred in July 2023

Chief Executive Officer, Graham Clarke, said: "The Khemisset Multi-mineral Process is an exciting, innovative development that represents a major improvement both environmentally and economically.

"The KMP arose from our team continuously exploring ways to minimise impact on the environment, particularly when it comes to water; we are always striving to protect this critical resource. It also forms part of the optimisation work that we had committed to do in discussions with water authorities in H1 2023. The KMP addresses these issues, while also delivering significant economic upside through the production of new fertiliser products to complement Khemisset's potash.

"The KMP transforms the environmental credentials of the Project by eliminating the requirement for the disposal of brines through DWI and significantly reducing process water consumption, both important points for the Moroccan authorities and local communities. We believe it further strengthens the case for approving our Environmental and Social Impact Assessment ("ESIA").

"Struvite and vivianite are multi-nutrient fertilisers containing phosphate, nitrogen, magnesium, and iron respectively. Their lower solubility means the nutrients are released over a longer period, and are less prone to being washed away by rain. This means that application rates can be less frequent, and phosphate run-offs that cause eutrophication of streams and lakes are significantly reduced.

"As part of our Scoping Study, we have updated our economic estimates for the Project, both based on the Original Design and the new KMP. Cost inflation since 2020 has inevitably resulted in an increase in capex of approximately 31% for the Original Design. In the case of the KMP, the elimination of DWI reduces this increase to 28%.

"More significantly, the addition of new revenue sources delivers considerable economic benefits, with the IRR of 40% for the Project including the KMP considerably higher than most potash projects in development.

"The KMP process sets a new benchmark for the industry. The Company is excited by the results of the study and is eager to progress the findings.

"With regards to the ESIA approval, we believe that the Moroccan authorities are continuing to assess the Company's application. We will provide further updates on all matters, including any formal notifications regarding the ESIA, in due course."

KMP Presentation

A presentation, outlining the KMP, is available on the Company's website, on the following page:

www.emmersonplc.com/investors/corporate-documents

Khemisset Multi-mineral Potash Process

Scoping Study

The Scoping Study describes a new process, the Khemisset Multi-mineral Process which was developed by Emmerson for use in the Khemisset potash project in Morocco.

The Scoping Study was compiled by Emmerson's in-house technical team, but incorporated sales and marketing reports from S&P Global and Mordor Intelligence, process plant design work from Barr Engineering, and testwork by the Saskatchewan Research Council, and Wardell Armstrong International.

The KMP process, in simple terms, involves the separation of magnesium and iron chlorides from the brines through the addition of phosphates and ammonia, creating in the process magnesium phosphate (struvite) and iron phosphate (vivianite) fertiliser products in addition to ammonium chloride, while allowing the brine to then be recycled back through the process plant for a better recovery rate of potassium. These products are thus in addition to the MOP product originally designed to be produced at Khemisset.

The KMP represents a transformational improvement to the Project both environmentally and economically.

The conversion of a waste stream (the brine containing magnesium and iron chloride) into further fertiliser products, struvite and vivianite, adds significantly to the sustainability of the Project. Any outcome that reduces waste is a positive but, in this case, an additional benefit is that the two products produced in its place are slow-release fertilisers, which allow farmers to reduce application rates and mitigate the negative impacts of fertiliser production, transportation, and usage from a carbon footprint and water run-off perspective.

Struvite and vivianite are likely to be suitable for use in climates susceptible to heavy rainfall events, where less soluble slow-release fertilisers reduce the risk of newly applied nutrients being washed away, which also causes problematic run off issues. In addition, slow-release products provide the nutrients when the plant requires them, allowing farmers to use less fertiliser and to apply less frequently.

Morocco is already a global fertiliser hub, so the ability to add not only potash but also these additional magnesium and iron phosphate products to its nutrient portfolio will enhance its position as a global agriculture and fertiliser lead, in particular on the African continent. The KMP requires a supply of both phosphate and ammonia, both of which will be available in Morocco, further reducing the negative impacts of transporting raw materials over longer distances.

The KMP involves relatively modest changes to the process plant, primarily through a reduction in crushing, and the addition of a separation stage and the creation of two separate decomposition stages (one magnesium and one iron).

As part of the Scoping Study, the economics of the Project have been refreshed and updated to reflect capex/opex and pricing movements since 2020. These are described in more detail below.

Process Basics

The KMP process involves the treatment of brine to extract magnesium and iron chlorides, producing magnesium phosphate (struvite) and iron phosphate (vivianite) fertilisers.

The ore that is processed at Khemisset is a mix of three potash-bearing minerals: sylvite, carnallite and rinneite. The original process was designed to handle this mix to produce the potash (MOP), and a brine waste containing magnesium chloride and iron chloride requiring disposal by DWI.

While sylvite contains only potassium chloride, carnallite ore also contains magnesium chloride, and rinneite contains iron chloride. The MOP production process requires that these impurities are removed, and the Original Design envisaged their disposal through injection into identified deep geological formations in a process known as DWI.

The KMP separates the rinneite-rich ores from the sylvite/carnallite ores once the Run of Mine ("RoM") ore has been presented to the front end of the treatment plant. This is a two-step process that generates separate brines with differing chemical profiles, one being a high magnesium chloride (low iron chloride) brine whilst the second is a high iron chloride (low magnesium chloride) brine.

The high magnesium chloride brine is further processed to produce a magnesium ammonium phosphate (Mg(NH4)PO4) fertiliser by-product (struvite) through the addition of phosphate and ammonia, whilst the high iron chloride brine is converted into a phosphate-based by-product in the form of hydrated ferrous phosphate (vivianite) (Fe3(PO4)2.8H2O).

Finally, the excess ammonia is removed from the two brine solutions as ammonium chloride (NH4Cl). The brines, now stripped of their contained magnesium chloride and iron chloride, are recycled back into the processing circuit and re-used, significantly reducing water consumption and improving the recovery of potash, as some of the potassium chloride and a considerable volume of water would otherwise be lost in the brine disposed of by DWI.

Process testwork validating the KMP design has been carried out by two internationally renowned metallurgical testing laboratories: the Saskatchewan Research Council (SRC), Canada, and Wardell Armstrong International (WAI), Cornwall, UK. Testing has included mineral liberation analysis, separation tests, mineral decomposition tests, brine processing and product agglomeration trials. Excellent results have demonstrated that the magnesium contained within carnallite, and the iron contained within rinneite, can be recovered from magnesium-rich and iron-rich decomposition brines and converted to struvite/vivianite and associated products respectively, at both very high grades and recovery levels.

Further testwork will be undertaken to optimise KMP and provide additional information in support of engineering design.

Struvite production

Struvite is magnesium ammonium phosphate (Mg(NH4)PO4). It is formed from the reaction between magnesium chloride brine with ammonium phosphate (diammonium phosphate ("DAP")), plus ammonia ("NH3").

Struvite is a known slow-release fertiliser that offers both nitrogen and phosphorous plus the benefit of magnesium which is an essential plant nutrient.

Vivianite production

Vivianite is hydrated ferrous phosphate (Fe3(PO4)2.8H2O). Ferrous phosphate formation is based on the reaction between ferrous chloride (brine) with DAP, plus ammonia.

Vivianite is a slow-release fertiliser that provides phosphorous, plus the benefit of iron, which is also an essential plant nutrient, although it is not currently marketed as such.

Ammonium Chloride

Ammonium chloride (NH4Cl) is a by-product in both of the DAP/brine reactions presented above.

Solid ammonium chloride is primarily used as a fertiliser, particularly in southeast Asia, but is also used to make dry batteries and ammonia compounds, as a soldering flux, and as a pickling agent in zinc coating and tinning.

The possibility of retaining the ammonium chloride in solution in order to reduce the quantity of ammonia required as a reagent is under consideration as potential further upside of the KMP.

Geology and Mining

The principal potash minerals in the Khemisset Basin are carnallite, sylvite, and rinneite. These are distributed in three sub-basins within the main basin.

Rinneite is rarely described in potash deposits, unlike sylvite and carnallite, which are more traditional targets for exploration and exploitation. However, the high content of potassium oxide ("K2O") (34.56%) in rinneite has been proven to be extractable through hot leaching and crystallisation by metallurgical testing previously carried out by Emmerson, and was therefore incorporated into the original potash processing route.

The KMP process means that different ore blends can be treated more efficiently, which offers the opportunity to improve the mine plan, and increase reserves. As well as the recovery of additional minerals from the ore, the recycling of brines will result in augmented MOP recoveries through the KMP, which will in turn allow lower cut-off grades and a further expansion of reserves and resource.

The KMP process is designed to handle carnallite, sylvite, and rinneite as planned to be extracted from the Khemisset resource in any reasonable ratio as determined by the mine plan. On this basis, no changes are necessary to the mining plan or mine access requirements as set out in the 2020 Feasibility Study.

However, the combined benefits of improved recovery of potash by eliminating the losses to DWI, as well as the recovery of magnesium chloride and iron chloride from the ore, means that the target mining horizon cut-off grades and mining height can be increased, allowing the use of larger machines, with increased cutting rates that means fewer machines are needed, reducing capex, opex and ventilation requirements. This assumption has been reflected in the economic evaluation of the KMP.

The KMP process will also enable a more detailed review of the mining plan, with the opportunity for an enhanced and flexible extraction strategy which is less reliant on a consistent ratio of ore.

A revised mining plan is a more detailed exercise that will be undertaken in due course.

Environment

The Company remains committed to developing the Project with minimal risk to the environment, and over more than three years has introduced a number of optimisations designed to mitigate potential environmental impacts.

The development of the KMP arose out of the general objective of the Company to minimise potential environmental impacts wherever possible, but also, importantly, reflects the interactions with the authorities whose particular focus is on water management, a precious resource in Morocco.

The KMP process represents a material improvement to the environmental footprint of the Project, most significantly in the elimination of DWI entirely, but also in the reduction in process plant water consumption by up to 60% (50% of the total water). In the context of concerns around water availability in Morocco, the importance of these benefits is difficult to overstate.

Disposing of brines through DWI, as envisaged in the original design, is still considered to be a good solution, but injectivity testing would still need to be performed to confirm the best location.

The KMP plant would also produce new fertiliser products that would enhance Morocco's credentials as a fertiliser hub and help address food security issues.

Sales and Marketing

Struvite

Struvite is currently mainly manufactured as a by-product of water treatment plants, where the natural phosphates recovered from wastewater are reacted with magnesium to produce small quantities of struvite, which is currently sold as a premium slow-release fertiliser in North America.

Struvite sales are therefore currently relatively small, with estimated production in 2022 of approximately 250 thousand tonnes, although a new facility has been announced to bring a further 200 thousand tonnes per annum ("ktpa") to the market in the US.

The KMP would produce around 750ktpa of struvite, which is considerably higher than the current market supply. However, in reality the struvite market is currently limited by production with demand potentially much higher as confirmed by marketing studies commissioned by Emmerson.

Furthermore, agronomic tests support struvite as being a premium slow-release source of phosphates as well as nitrogen and magnesium, able to attract a premium price, particularly as KMP-produced struvite will contain no deleterious heavy metal elements that exist in struvite from water treatment plants.

A S&P Global report, commissioned by Emmerson, estimated a value based on the nutrient content of struvite as US$424/t. However, Mordor Intelligence reported that actual struvite prices in North America are in excess of US$1,000/t. Emmerson has taken a more conservative position between these extremes, particularly in view of the size of the current market and has assumed US$500/t in its economic model, which nonetheless delivers considerable value.

Vivianite

Vivianite is not currently sold in significant quantities as a fertiliser but shares similarities with struvite in that both are slow-release phosphate fertilisers containing an additional micronutrient. Struvite contains magnesium and vivianite contains iron, with both micro-nutrients seen in existing fertiliser blends depending on crop requirements.

As with struvite, it is realistic that a premium price is achievable, although the base case financials assume a sales price derived from nutrient content of US$299/t, as estimated by S&P Global.

Ammonium chloride

Ammonium chloride is an inorganic compound used to make dry batteries and ammonia compounds, as a soldering flux, as a pickling agent in zinc coating and tinning, and as a fertiliser. Ammonium chloride has a relatively established market.

Costs and Financials

As part of understanding the economic impact of KMP, it was necessary to update the financial model for the Project both based on its Original Design, and after incorporating the changes from integrating the KMP process.

The starting point for this process was the financial model included in the 2020 Feasibility Study, which was prepared in detail by Golders, and which was originally announced in June 2020.

The revised figures, used in updating the 2020 Feasibility Study, take into account revised pricing expectations for specific items of plant and mining equipment, as well as input costs such as electricity, LPG, and diesel. Where relevant, the estimations also include updates arising from optimisations (such as the switch to dry-stack tailings, the incorporation of four declines rather than two, and the sourcing of water from Khemisset waste-water treatment plant), and the basic engineering work completed on the process plant by Barr Engineering and on mine access and other infrastructure by Reminex SA.

Key Performance Indicators

A summary of the key financials of the KMP compared with the Original Design and the 2020 Feasibility Study is as follows:

It should be noted that the project offers considerable upside in the event of higher prices being achievable (notably struvite), while also being resilient to a lower price environment, including for potash. The following tables illustrate the NPV8 and IRR of the project incorporating the KMP enhancement at various MOP and struvite prices.

Capex

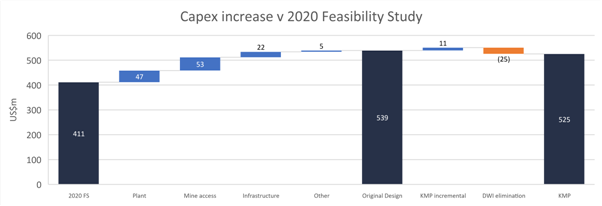

Updated financials for the Original Design reflect cost inflation, as well as the impact of optimisations and improvements since the 2020 Feasibility Study. Overall, this resulted in capex increasing by 30% from US$411 million to US$539 million, which is broadly in line with process plant equipment price index movements over that period, as well as cost increases experienced by other mining projects.

The KMP capex is slightly lower at US$525 million, with US$25 million saved from eliminating DWI mitigated by US$11 million of additional equipment in the process plant.

Potash Costs

Cash costs (excluding the KMP additional products) for both KMP and Original Design have also increased since 2020, with inflation impacting energy, equipment, and other operating costs, mitigated by operating efficiencies (particularly in mining).

KMP unit costs are lower than the Original Design primarily due to the improved recoveries of potash as a result of recycling brines back into the circuit.

KMP Unit Costs

The KMP products are, like salt, by-products of the potash process, but their expected unit margins are sufficiently large that it is not meaningful to show their value as a net credit to potash costs.

Instead, the table below shows their estimated production costs per tonne. It should be noted that ammonium chloride is considered a secondary by-product, and KMP costs have been allocated to struvite/vivianite only.

Pricing Assumptions

The following price assumptions were used in the economic assessment:

MOP prices were kept in line with 2020 assumptions. Although prices rose dramatically in 2021 and 2022, fertiliser prices have now normalised.

Struvite prices were estimated to be US$500/t. S&P Global estimated the value of the contained nutrients to be US$424/t, to which a conservative premium was applied to reflect the incremental benefit of being a multi-nutrient, slow-release product.

Vivianite price assumptions were based on S&P Global's estimates of nutrient content. Vivianite has similar qualities to struvite, and it is therefore reasonable to expect a premium, however, a more conservative assumption was adopted to reflect the lack of an established market.

Other pricing assumptions were based on current pricing levels.

Opportunities and Next Steps

The KMP Scoping Study and updated financials underlines the robust financials of the Original Design but outlines that the new process will deliver significant improvements both in terms of environmental impact (particularly relating to water management), and economically.

Further enhancements can also be anticipated that are not, as yet, incorporated into the economic analysis. These include the following:

· Redesigning the mine plan to take into account the improved potash recoveries and a wider range of economically extractable minerals made possible by the KMP

· Exploring more cost-efficient sources of phosphate (e.g. monoammonium phosphate (MAP)) to lower production costs

· Drying of struvite to reduce water content and create a higher value product (dittmarite)

· Recycling ammonium chloride to reduce requirement of ammonia

· Negotiating sources of key reagents, notably phosphates and ammonia

· Developing marketing plans for struvite and vivianite and signing offtake agreements

· Option to develop on-site blending with MOP for production of a variety of multi-mineral fertilisers

· Processing IP could be transferrable to other operations in Morocco and beyond

The Company will then move forward with discussions with key suppliers, offtakers and other stakeholders regarding this new optimisation. Further testwork, crop studies, and design amendments will then be fed back into the overall project design, before ultimately being incorporated into a revised bankable feasibility study (including an updated mine plan), ahead of completing financing and commencing construction.

Market Abuse Regulation (MAR) Disclosure

This announcement contains inside information for the purposes of the UK Market Abuse Regulation and the Directors of the Company are responsible for the release of this announcement.

Competent Persons' Statement

The technical information in this report is based on information reviewed by Mr. Graham Clarke, a Competent Person who is a BEng Mining Engineering and a Fellow of the Institute of Materials, Minerals and Mining. Mr. Clarke is employed by Emmerson PLC and has sufficient experience which is relevant to the information reported here. Mr Clarke consents to the inclusion in the report of the matters based on his information in the form and context in which it appears.

**ENDS**

For further information, please visit www.emmersonplc.com, follow us on Twitter (@emmerson_plc), or contact:

|

Emmerson PLC Graham Clarke / Jim Wynn / Charles Vaughan

|

+44 (0) 207 138 3204 |

|

Liberum Capital Limited (Nominated Advisor and Joint Broker) Scott Mathieson / Matthew Hogg / Kane Collings

|

+44 (0)20 3100 2000 |

|

Shard Capital (Joint Broker) Damon Heath / Isabella Pierre

|

+44 (0)20 7186 9927

|

|

BlytheRay (Financial PR and IR) Tim Blythe / Megan Ray / Said Izagaren

|

+44 (0) 207 138 3204 |

Notes to Editors

Emmerson is focused on advancing the Khemisset project ("Khemisset" or the "Project") in Morocco into a low cost, high margin supplier of potash, and the first primary producer on the African continent. With an initial 19-year life of mine, the development of Khemisset is expected to deliver long-term investment and financial contributions to Morocco including the creation of permanent employment, taxation, and a plethora of ancillary benefits. As a UK-Moroccan partnership, the Company is committed to bringing in significant international investment over the life of the mine.

Morocco is widely recognised as one of the leading phosphate producers globally, ranking third in the world in terms of tonnes produced annually, and the development of this mine is set to consolidate its position as the most important fertiliser producer in Africa. The Project has a large JORC Resource Estimate (2012) of 537Mt @ 9.24% K2O, with significant exploration potential, and is perfectly located to support the expected growth of African fertiliser consumption whilst also being located on the doorstep of European markets. The need to feed the world's rapidly increasing population is driving demand for potash and Khemisset is well placed to benefit from the opportunities this presents.

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.

Latest directors dealings

- 27 minutes ago Johnson Matthey

- 2 hours ago THG

- 3 hours ago ASA International Group

- 3 hours ago Rio Tinto

- 3 hours ago Dunelm Group